Sheet Metal Artifacturing

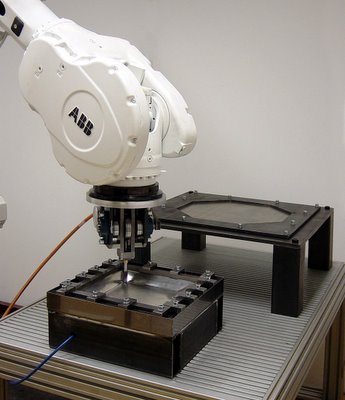

Robot hammers on sheet metal

Rapid prototyping makes it possible to quickly produce or modify tools and structural components, as one-off jobs or in small batches. A unique process allows 3D portraits and other patterns to be hammered into car bonnets or other sheet metal.

“Incremental” means hammering or pressing a part into shape in gradual stages. In the metal-hammering process developed at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, a robot guides an oscillating punching tool in circular movements over the fixed sheet of metal. It gradually creates a relief pattern corresponding to the computer template. It takes less than 15 minutes to convert a CAD model into a real object measuring 10 x 10 centimeters.

For instance, it allows high-end customers to modify cars sporting their logo as a relief pattern incorporated in the bonnet, or as a permanent inscription in the fender. Car bodies can also be enhanced with ribbed styling to emphasize their aerodynamic performance. This would be a great asset for show cars, which are not destined for mass production.

Fraunhofer-Gesellschaft 11-2005-Top3

0 Comments:

Post a Comment

<< Home