Printing with Clay on Prototype Machines

From Ceramics Monthly comes a recipe for 3D printing ceramics clay and description of development of process.

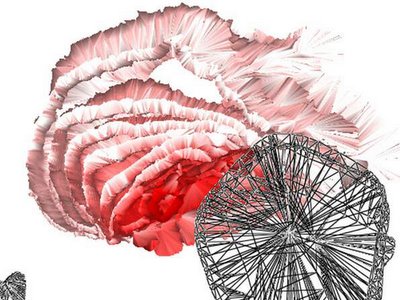

In the Solheim Rapid Manufacturing Laboratory (located in the Mechanical Engineering Building at the University of Washington in Seattle), our research focuses on new and improved methods to describe complex shapes in a way that a computer can “understand” and to fabricate those shapes in ways that the computer can control (a.k.a., rapid prototyping).

***

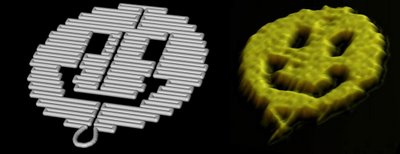

The actual build process goes as follows. The 3DP system’s software slices the object into layers ranging from 0.003 inches to 0.013 inches thick. A layer of powder matching the thickness of the digital layer (in our case 0.005 inches) is spread onto a build platform, or print bed. An ink-jet printing system deposits binder into the powder layer corresponding to the image of the current layer. The print bed is lowered, another layer of powder is spread, another slice is printed, and the system continues until all layers are processed. When the 3D print is finished, our object composed of bound powder is supported in a bed of unbound powder. We now remove the unbound powder to reveal our finished object by a combination of manual brushing, vacuum removal and compressed air (see p. 38). At times, one feels a bit like an archeologist at a dig site—and often with just as much excitement.

After an object is removed from the bed and de-powdered, one of a variety of post-processing techniques may be employed to “finish” the object, depending on its final use. Post-processing options include wax infiltration, epoxy infiltration, CA (CyanoAcrylate) glue infiltration, elastomer infiltration, or painting. These final steps often enable the part to function as a true prototype rather than just a form-and-feel object. For our ceramic-slip parts, post-processing consisted of kiln-firing, glazing, and glaze firing.

***

recipes

| PVA Printing Slip | |

| Xtra-White, Redart TerraCotta or Stoneware Buff Slip . . . . . . . . . . . . . . . | 62.50 % |

| Sugar (extra fine) . . . . . . . . | 31.25 |

| PVA (PolyVinyl Alcohol) . . . | 6.25 |

| | 100.00 % |

| MaltoDextrin Printing Slip | |

| Xtra-White, Redart TerraCotta or Stoneware Buff Slip . . . . . . . . . . . . . . . | 66.66 % |

| Sugar (extra fine) . . . . . . . . | 16.67 |

| MaltoDextrin . . . . . . . . . . . . | 16.67 |

| | 100.00 % |

The PVA Printing Slip mixture produced quite acceptable results (with all slips) but the PVA is a little more costly when compared to MaltoDextrin (which is available at the grocery store under the brand name Benefiber). The MaltoDextrin Printing Slip was also stronger in greenware form.

A solution of 16–18% ethanol (by volume) in water with a bit of food coloring works nicely as a binder. The food coloring lets you see if the fluid is deposited properly, and it burns out during firing. Our ethanol-water solution is vodka based (denatured alcohol tended to clog the printhead), so don’t tell your graduate students how it’s made.

***

Ceramics Monthly Feature Printing with Clay on Prototype Machines