Ping Fu: Recreating the World in All Its Dimensions

You may have never heard of Ping Fu. But chances are her work has touched you in some way. Fu has spent decades envisioning new uses for computers. Now she thinks she's really on to something: a technology that can scan three-dimensional objects, recreating them first virtually, and then in the real world.

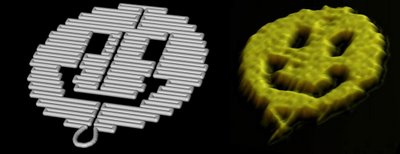

Fu came to American in 1982 and co-founded her company, Geomagic, in 1996. It is headquartered in a non-descript building in North Carolina's Research Triangle Park. The company's products enable designers and engineers to scan a 3-D object, capture the data from the scan and then use it to create highly accurate digital models.

Virtual 3-D images can be inspected, redesigned and tested, and used to manufacture perfect replicas.

Fu says doctors will soon use the technology to custom-make prosthetic joints and other medical devices that fit and function better. And eventually, she predicts, even clothes and shoes will be made-to-order this way. She calls this "mass customization" and says it will make today's mass production obsolete. Stores stacked to the ceiling with blue jeans will seem quaint -- even silly, she says.

[Picture shown is Noveletti soap holder. Geomagic software gives Noveletti the design freedom they need for their unique products.]

NPR : Ping Fu: Recreating the World in All Its Dimensions: "Invisiline "