Charles Choi

Three-dimensional tubes of living tissue have been printed using modified desktop printers filled with suspensions of cells instead of ink. The work is a first step towards printing complex tissues or even entire organs.

"This could have the same kind of impact that Gutenberg's press did," claims tissue engineer Vladimir Mironov of the Medical University of South Carolina.

Many labs can now print arrays of DNA, proteins or even cells. But for tissue engineers, the big challenge is creating three-dimensional structures. Mironov became interested when Thomas Boland of Clemson University, also in South Carolina, told Mironov how he could print biomaterials using modified ink-jet printers.

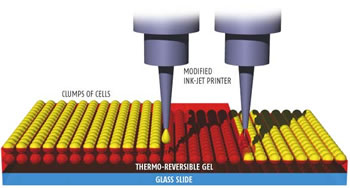

The printers are adapted by washing out the ink cartridges and refilling them with suspensions of, say, cells. The software that controls the viscosity, electrical resistances and temperature of the printing fluids is reprogrammed and the feed systems altered.

To create 3D structures, Boland and Mironov used a "thermo-reversible" gel recently developed by Anna Gutowska at the Pacific Northwest National Laboratory in Richland, Washington. The non-toxic, biodegradable gel is liquid below 20 °C and solidifies above 32 °C.

The team has done several experiments using easily available tissues such as hamster ovary cells. By printing alternate layers of the gel and clumps of cells onto glass slides, they have shown 3D structures such as tubes can be built up.

Mironov and Boland hope it will be possible to print the entire network of arteries, capillaries and veins that nourish organs. But to keep cells alive, the organs would have to be completed within a couple of hours and a growth medium circulated through the fragile new vessels.

New Scientist Breaking News - Ink-jet printing creates tubes of living tissue